Tier One

Tier One Rings

Tier one picatinny rings are the toughest, lightest and most accurate aluminum scope rings available for any kind of precision rifle shooting.

Their low profile, elegant design suits most setups and offers unparalleled accuracy and extremely high tolerances.

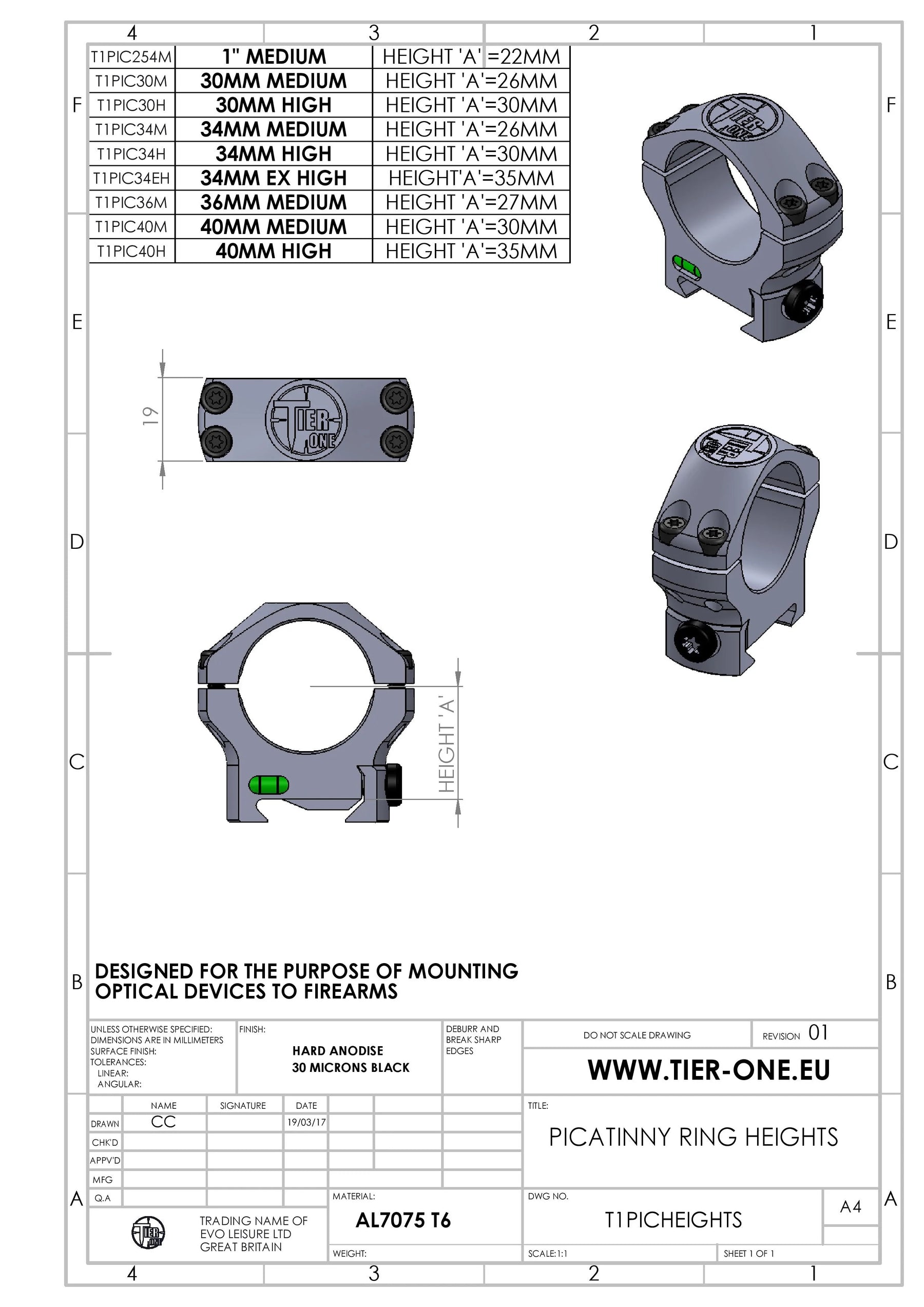

QUICK SPECS

- Manufactured from high grade 7075T6 aluminium

- No lapping required - perfectly matched pairs

- Four screw ring caps for secure optic mounting

- Mill spec 30 micron hard anodised finish

- One hit machining to ensure repeatability

- Built in anti-cant bubble

MATERIALS

When you buy from Tier One we want you to have a quality product that lasts a lifetime. That’s why we invest in the highest quality materials available for all of our products.

These Picatinny Scope Rings are manufactured from solid 7075T6 aluminum, an aerospace alloy that offers one of the highest strength to weight ratios of any alloy currently available.

The screws we use in these scope mounts are manufactured by us, in house, to our own exact specifications, so they match the product perfectly and result in zero accuracy loss.

These materials are the finest available and combined with the rings’ efficient and elegant design they will offer you the maximum weight saving possible with the absolute maximum accuracy and repeatability of any rifle scope mount on the market right now.

CONSTRUCTION

We use high tech 5 axis CNC milling machines and advanced manufacturing and finishing processes to ensure that every possible inaccuracy or loss of tolerance is eliminated in the making of these scope rings.

The ring pair is milled at the same time from the same solid billet of aluminium, and the whole process is completed in one operation. What this means for you is a pair of rings that are perfectly matched to each other, and which have not suffered any loss of accuracy due to resetting machines.

Most mass-manufactured AR & Rifle scope mounts are produced on inferior machinery in multiple operations, which means the rings and tools are moved out of alignment each time a new piece of the ring-set is machined, resulting in huge losses of accuracy across the whole process. We do not do this.

Every set of picatinny scope rings is mechanically deburred in a machine using hundreds of ceramic balls to achieve a perfectly smooth finish before anodising in hard black 30 micron thickness, and the logo is also fully anodised resulting in a blacked-out look.